Page 189 - Catalogue 2019

P. 189

flange ring

seat

stud bolt

gland follower

screw nut and washer

packing gland

O-ring

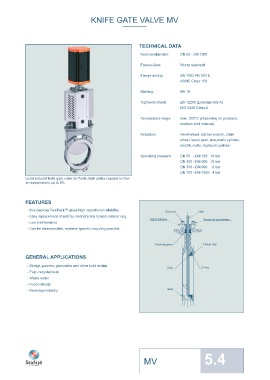

KNIFE GATE VALVE MV slibody KNIFE GATE VALVE MV

TECHNICAL DATA

MATERIAL SPEZIFICATION AND PARTS LIST

Nominal diameter: DN 50 - DN 1200 1 1e

Face-to-face: Works standard 2 1d

2b 18

2a

Flange drilling: EN 1092 PN 10/16 5b

ASME Class 150 3 5a

4 5

Marking: EN 19

4a

Tightness check: EN 12266 (Leakage rate A) 4b

ISO 5208 Class A 15

7 16

8c

Temperature range: max. 300°C (depending on pressure, 6

medium and material) 8b

8a 10a

11

Actuators: Hand wheel, ratchet wrench, chain 8 9

wheel, bevel gear, pneumatic cylinder, 9a 14

electric motor, hydraulic cylinder 10b

12a 10

Operating pressure: DN 50 - DN 125: 16 bar 12 13

DN 150 - DN 300: 10 bar

DN 350 - DN 600: 6 bar

DN 700 - DN 1600: 4 bar Parts list of DN 50 - DN 800 (monobloc valve body) Parts list of DN 900 - DN 1600 (Two piece valve body)

Unidirectional knife gate valve for fluids, bulk solids capable to flow

an suspensions up to 5%.

Pos. Part Material (Name) Pos. Part Material (Name)

1 Hand wheel Coated cast iron, EN-JL1040, EN-JL1030 8a Stud bolt Stainless steel (A2), zinc coated

2 Yoke Stainless steel (EN 1.4301) 8b Washer Stainless steel (A2)

FEATURES 2a Bearing Brass (CuZn39Pb3) 8c Nut Stainless steel (A2), zinc coated

Slide washer

2b

Twin Pack™

Box packing

9

POM

- Box packing TwinPack™ gives high operational reliabililty Stud bolt Slide 3 Stem Stainless steel (EN 1.4016 alt. EN 1.4305) 9a Box bottom support HD-polyethylene

- Easy replacement of seat by mechanically locked retainer ring 4 Stem nut Brass (CW603N alt. CW614N) 10a/b Valve body Stainless steel (A2)

Gland follower Screw nut and washer 4a Washer Stainless steel (A2) 11 Body gasket PTFE

- Low maintenance 4b Screw Stainless steel (A2) 12 Retainer ring Stainless steel (A2)

5 Tie rod Stainless steel (EN 1.4301) 12a Locking screw Stainless steel (A2)

- Can be disassembled, material specific recycling possible

5a Washer Stainless steel (A2) 139 Seat EPDM

5b Nut Stainless steel (A2) 14 Guiding pads HD-polyethylene

6 Gate See equipment B 15 Bushing Oil-bronze

Packing gland Flange ring 7 Beam Aluminium (EN AW-6063-T6) 16 Gate guard, not for HW Stainless steel (EN 1.4301)

8 Gland Stainless steel, Coated nodular iron

* Recommended spare parts Subject to change without notice

GENERAL APPLICATIONS

- Sludge, powder, granulates and other solid media

Seat O-ring

- Pulp, recycled pulp

-Waste water

- Food industry

- Beverage industry Body

MV 6.2 www.ebro-armaturen.com

MV 5.4 post@ebro-armaturen.com

01.2019