Page 19 - Catalogue 2019

P. 19

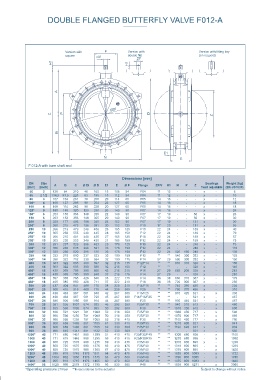

DOUBLE FLANGED BUTTERFLY VALVE F012-A DOUBLE FLANGED BUTTERFLY VALVE F012-A

MATERIAL SPECIFICATION AND PARTS LIST

Version with F Version with Version with fitting key

square □V double flat (on request) Type of bearings: Type of bearings:

ZF Fixed Adjustable

H1 H1 3

5 20

4

19

splitted shaft 1 18

5 2

A 6 6 6

5

5 5

ØDi 8

C P D 8 10

Z 8

11

5

12

19

B 20

4

5 5

7 5 3 4

9

5 13 16

E1

N E 14 5 15 14 17

F 012-A with bare shaft end 15 TS-Version TS-Version PS max 19 bar up to DN 350

with pinned shaft with splitted shaft PS max >19 bar up to DN 250

Double flanged butterfly valve F012-A PS max 19 bar

Dimensions [mm]

DN Size Bearings Weight [kg]

[mm] [inch] A B C Ø Di Ø D E1 E Ø F Flange ZF/V H1 N P Z fixed adjustable (EN-JS1030) Pos. Description Material Material-No. Pos. Description Material Material-No.

50 2 126 84 210 48 165 18 108 54 F04 11 12 - - - x - 6 1 Body 10 Taper pin

65 2 1/2 134,5 93,5 228 63 185 18 112 54 F04 11 12 - - - x - 10 Nodular Cast Iron EN-GJS-400-15 EN-JS1030 Stainless Steel X5CrNi18-10 1.4301

80 3 157 104 261 78 200 20 114 65 F05 14 16 - - - x - 12 Carbon Steel GP240GH 1.0619 G-X5CrNiMo19-11-2* 1.4408*

100* 4 168 127 295 98 254 22 127 65 F05 14 16 - - - x - 18 2 Seat/vulcanization 11 Washer

100 4 168 114 282 98 228 20 127 65 F05 14 16 - - - x - 18 NBR Nitrile butadiene rubber Stainless Steel A4

125* 5 180 140 320 123 280 26 140 90 F07 14 16 - - - x - 24 EPDM Ethylene propylene diene monomer rubber 12 Hex nut

150* 6 203 150 353 148 285 22 140 90 F07 17 19 - - 56 x - 26 3/4 Bearing bush Stainless Steel A4

150 6 203 153 356 148 305 29 140 90 F07 17 19 - - 56 x - 30 Brass CuZn39Pb3 CW614N 13 Shaft retention

200 8 229 177 406 198 345 24 152 90 F07 17 19 - - 131 x - 30 5 O-Ring Brass CuZN39Pb3 CW614N

200* 8 260 215 475 198 381 30 152 125 F10 17 20 - - 131 x - 56 NBR Nitrile butadiene rubber Stainless Steel 16MnCr5* 1.7131*

250 10 266 213 479 248 406 26 165 125 F10 22 24 - - 189 x - 40 EPDM Ethylene propylene diene monomer rubber 14 Cover plate

250* 10 305 250 555 248 445 28 165 150 F12 22 24 - - 189 x - 79 6/7 Shaft Sectional steel S235JR

250* 10 266 215 481 248 430 27 165 125 F10 22 24 - - 189 x - 57 X14CrMoS17 1.4104 Nodular Cast Iron EN-GJS-400-15 EN-JS1030

250* 10 305 250 555 248 430 21 165 150 F12 22 24 - - 189 x - 75 X2CrNiMo17-12-2 1.4122 15 Screw

300 12 291 237 528 296 483 28 178 125 F10 22 24 - - 240 x - 73

300* 12 350 285 635 296 521 33 178 150 F12 22 24 - - 240 x - 110 X5/(X2)CrNiMo17-12-2 1.4401/1.4404 Steel 45 H galvanized

300* 12 335 285 620 296 515 36 178 150 F12 22 24 520 150 240 x - 108 G-X5CrNiMo19-11-2 1.4408 Stainless Steel A4-70

350 14 332 278 610 337 533 33 190 150 F12 ** ** 540 300 282 x - 103 G-X2CrNiMoN26-7-4 1.4462 16 Seal DIN 915

350* 14 390 322 712 338 584 32 190 175 F14 27 29 590 300 282 x - 150 CuAl10Fe5Ni5-C 1.4469 Cooper Cu

400 16 363 322 685 390 597 32 216 175 F12/F14 ** ** 610 310 328 x - 150 X5CrNiCuNb 16-4* 1.4452* 17 Plug screw DIN 908

400 16 363 322 685 390 580 32 216 150 F12 ** ** - - 328 x - 140 8 Disc Machining steel 11SMnPb30 1.0718 nickel-plated

400* 16 435 360 795 390 660 42 216 210 F16 27 29 665 200 328 x - 215 Nodular Cast Iron EN-GJS-400-15 EN-JS1030 Stainless Steel G-X5CrNiMo19-11-2 1.4408

400* 16 430 360 790 390 648 37 216 175 F14 27 29 - - 328 x - 210 Stainless Steel G-X5CrNiMo19-11-2 1.4408 18 Threaded pin DIN 915

450* 18 397 368 765 426 640 33 222 175 F14 36 38 680 310 367 x - 179 G-X2CrNiMoN26-7-4* 1.4469* Steel 45 H galvanized

450* 18 465 385 850 426 711 37 222 210 F16 36 38 720 300 367 x - 250 Aluminium Bronze CuAl10Fe5Ni5-C CC333G Stainless Steel X5CrNiMo17-12-2 1.4401

500 20 437 404 841 489 715 38 229 210 F14/F16 ** ** 740 350 436 x - 204 Coating Halar, Rilsan, Nonstick 19 Clamping ring

500* 20 500 415 915 489 775 44 229 300 F25 ** ** 790 370 436 x - 310 Surface quality electropolished, mirror finished Sectional steel S235JR

600 24 498 469 967 581 840 42 267 300 F16/F25 ** ** 870 420 521 - x 330 9 Sleeve 20 Cylinder screw

600 24 498 469 967 581 790 45 267 300 F14/F16/F25 ** ** - - 521 x - 467 Stainless Steel X5CrNi18-10 1.4301 Stainless Steel A4

600* 24 580 500 1080 581 914 44 267 300 F25 ** ** 930 440 521 - x 457 Subject to change without notice

700 28 581 526 1107 674 935 46 292 350 F25/F30 ** ** 940 510 612 - x 480 *Materials for valves ≥19 bar

700* 28 635 560 1195 674 995 50 292 350 F30 ** ** 1010 350 612 - x 600

800 32 630 591 1221 781 1060 52 318 350 F25/F30 ** ** 1080 450 717 - x 598

800 32 660 590 1250 781 1060 50 318 350 F25/F30 ** ** 1070 600 717 - x 666

800* 32 660 595 1255 781 1085 55 318 415 F35 ** ** 1100 450 717 - x 760

900* 36 800 685 1485 881 1185 61 330 415 F30/F35 ** ** 1210 600 821 - x 941

900 36 800 685 1485 881 1185 52 330 350 F25/F30 ** ** 1190 620 821 x - 932

900 36 696 645 1341 881 1122 52 330 300 F25 ** ** - - 821 x - 650

1000* 40 771 680 1451 980 1290 51 410 475 F30/F35/F40 ** ** 1300 680 895 - x 1100

1000 40 771 675 1446 980 1255 56 410 415 F25/F30/F35 ** ** 1270 680 895 - x 1092

1000 40 850 725 1575 980 1275 59 410 475 F35/F40 ** ** 1310 600 895 x - 1245

1000* 40 850 725 1575 980 1275 62 410 475 F35/F40 ** ** 1310 600 895 - x 1239

1000* 40 850 725 1575 980 1360 67 410 475 F35/F40 ** ** 1370 600 895 - x 1426

1200 48 935 810 1745 1176 1511 54 470 475 F35/F40 ** ** 1520 800 1083 - x 1722

1200* 48 1004 862 1866 1176 1575 63 470 560 F40/F48 ** ** 1590 800 1085 - x 1785

1200 48 905 810 1715 1176 1455 60 470 350 F25/F30 ** ** 1475 600 1083 x - 1440

1400* 56 1120 958 2078 1372 1795 86 530 560 F48 ** ** 1830 800 1271 - x 3060

*Operating pressure ≥19 bar **In accordance to the actuator Subject to change without notice