Page 79 - Catalogue 2019

P. 79

DOUBLE FLANGED BUTTERFLY VALVE Z 612-A DOUBLE FLANGED BUTTERFLY VALVE Z 612-A

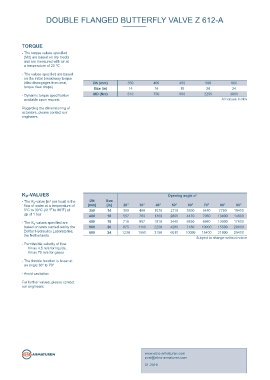

TECHNICAL DATA TORQUE

Nominal diameter: DN 350 - DN 600 - The torque values specifi ed

(Md) are based on dry media

Face-to-face: EN 558 Series 20 and are measured with air at

a temperature of 20 °C

ISO 5752 Series 20

API 609 Table 1 - The values specifi ed are based

on the initial breakaway torque

Flange connection: EN 1092 PN 10/16 (disc disengages from seat, DN (mm) 350 400 450 500 600

ASME Class 150 torque then drops) Size (in) 14 16 18 20 24

- Dynamic torque specifi cation MD (Nm) 610 750 860 2255 3000

Flange Surface Design: EN 1092 Form A/B available upon request All values in Nm

ASME RF, FF

Regarding the dimensioning of

Top fl ange: EN ISO 5211 actuators, please contact our

engineers.

Marking: EN 19

Tightness check: EN 12266 (Leakage rate A)

ISO 5208, Categroy 3

Temperature range: -40°C to +200°C (depending on

pressure, medium and material)

Operating pressure: max. 10 bar

Resilient seated double fl anged butterfl y valve for semi-corrosive

media with split body

K -VALUES Opening angle α°

v

FEATURES - The K -value [m³ per hour] is the DN Size

v

fl ow of water at a temperature of [mm] [in] 20° 30° 40° 50° 60° 70° 80° 90°

- One piece disc/shaft 5°C to 30°C (41°F to 86°F) at 350 14 399 488 1070 2110 3590 5480 7760 10400

- Split body with stainless steel screws ∆p of 1 bar 400 16 557 703 1360 2600 4470 7060 10400 14600

- Insulation height as per plant regulations - The K -values specifi ed are 450 18 716 907 1810 3440 5830 8980 13000 17800

v

- Optional: Special design RWTÜV certifi ed to TA-Air/ VDI 2440 based on tests carried out by the 500 20 875 1110 2250 4280 7180 10900 15500 20900

Delfter Hydraulics Laboratories, 600 24 1230 1550 3150 6010 10090 15400 21800 29400

- Disc`s sealing surface mirror polished the Netherlands Subject to change without notice

- Materials complying with FDA standards available

- Can be disassembled, material-specifi c recycling possible - Permissible velocity of fl ow

Vmax 4,5 m/s for liquids,

- For paint and laquers, a silicone-free version is available Vmax 70 m/s for gases

- The throttle function is linear at

an angle 30° to 70°

- Avoid cavitation

GENERAL APPLICATIONS

For further values, please contact

- Food and beverage industry our engineers.

- Purifi cations plants

- Pharmaceutical industry

- Chemical and petrochemical industry

- Water and waste water industry

- Pneumatic materials handling technology The split body design allows quick and easy maintenance.

- Shipbuilding

- Power plants

- Civil engineering

post@ebro-armaturen.com

Z 612-A 1.19 www.ebro-armaturen.com

01.2019