Page 88 - Catalogue 2019

P. 88

PTFE-LINED BUTTERFLY VALVE T 211-A PTFE-LINED BUTTERFLY VALVE T 211-A

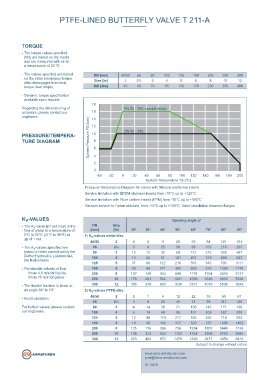

TECHNICAL DATA TORQUE

Nominal diameter: DN(40) 50 - DN 300 - The torque values specifi ed

(Md) are based on dry media

Face-to-face: EN 558 Series 20 and are measured with air at

ISO 5752 Series 20 a temperature of 20 °C

API 609 Table 2

- The values specifi ed are based DN [mm] 40/50 65 80 100 125 150 200 250 300

Flange accommodation: EN 1092 PN 10/16 on the initial breakaway torque Size [in] 2 2½ 3 4 5 6 8 10 12

ASME Class 150 (disc disengages from seat,

AS 4087 torque then drops) MD [Nm] 40 40 70 95 130 170 230 350 480

Flange Surface Design: EN 1092 Form A/B - Dynamic torque specifi cation

ASME RF, FF available upon request

18

Top fl ange: EN ISO 5211 Regarding the dimensioning of DN 50 - 150, special design

actuators, please contact our 16

Marking: EN 19 engineers. 14

Tightness check: EN 12266 (Leakage rate A) 12

Temperature range: -40°C to +200°C 10 DN 50 - 300

(depending on operation pressure) PRESSURE/TEMPERA- System Pressure PS (bar)

TURE DIAGRAM 8

Operating pressure: max. 10 bar (16 bar for special version) 6

Vacuum: up to 1 mbar absolute

(with silicon elastomer inserts) 4

from -10°C bis +160°C 2

0

-40 -20 0 20 40 60 80 100 120 140 160 180 200

Fully PTFE-lined wafer type valve for corrosive and aggressive System Temperature TS (°C)

media. The patented shaft seal design ensures reliability even with

high-corrosive applications. Pressure-Temperature-Diagram for valves with Silicone elastomer inserts

Service limitation with EPDM elatomer inserts from -10°C up to +120°C

FEATURES Service limitation with Fluor carbon inserts (FPM) from -10°C up to +180°C

Vacuum service to 1mbar absolute, from -10°C up to +160°C. Valve installation between fl anges

- PTFE-lined butterfl y valve for chemically toxic and highly

corrosive media

v

- Environmental protection via EBRO-Safety seal K -VALUES Opening angle α°

- Splitted body design - The K -value [m³ per hour] is the DN Size

v

fl ow of water at a temperature of [mm] [in] 20° 30° 40° 50° 60° 70° 80° 90°

- Isolation height according to plant prescription 5°C to 30°C (41°F to 86°F) at

- Can be installed in any desired position ∆p of 1 bar 1) K v -values metal disc

- Maintenance-free 40/50 2 4 2 11 28 53 84 121 161

- The K -values specifi ed are 65 2½ 5 8 25 56 99 153 216 287

v

- Can be disassembled, material-specifi c recycling possible based on tests carried out by the 80 3 13 12 30 69 131 216 328 467

- Material conform to FDA EG 1935/2004 Delfter Hydraulics Laboratories, 100 4 13 25 61 121 207 319 459 627

the Netherlands

- Optional: Special design RWTÜV certifi ed to TA-Air/ VDI 2440 1 2 125 5 37 66 122 216 353 543 793 1111

- Permissible velocity of fl ow 150 6 50 94 171 303 509 810 1226 1778

Vmax 4,5 m/s for liquids, 200 8 137 149 344 696 1178 1764 2426 3137

GENERAL APPLICATIONS Vmax 70 m/s for gases 250 10 178 291 562 1021 1699 2626 3832 5348

- The throttle function is linear at 300 12 395 378 820 1638 2751 4079 5538 7049

- Chemically highly corrosive and toxic media an angle 30° to 70° 2) K -values PTFE-disc

v

- Purifi cation plants 40/50 2 2 1 4 12 22 35 50 67

- Avoid cavitation

- Pharmaceutical industry 65 2½ 3 9 26 48 74 98 117 126

- Adhesives, paper industry, dissolver For further values, please contact 80 3 4 14 38 71 108 143 171 186

our engineers. 100 4

- Paint manufacture and processing Safety seal at both shaft ends: 6 16 48 95 151 209 262 303

- Food industry 1.Primary sealing by means of a belleville spring washer, trans- 125 5 12 40 110 217 356 525 718 933

787

18

526

60

- Transport of hazardous materials (EN 14432) mitting prestress on the spherical segment area. 150 6 8 125 176 161 317 1234 1807 1096 1452

2.Secondary sealing of the shaft by means of PTFE-Chevron and

200

3136

756

395

2449

- Chlorine production o-ring.

250 10 138 333 644 1103 1744 2599 3702 5086

- Processing of ore 300 12 203 462 872 1479 2329 3471 4950 6814

Subject to change without notice

post@ebro-armaturen.com

T 211-A 2.1 www.ebro-armaturen.com

01.2019