Page 89 - Catalogue 2019

P. 89

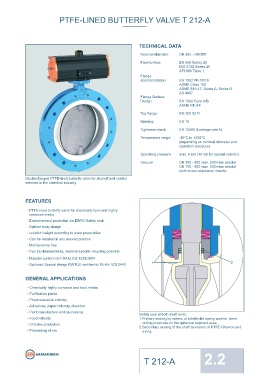

PTFE-LINED BUTTERFLY VALVE T 212-A PTFE-LINED BUTTERFLY VALVE T 212-A

TECHNICAL DATA TORQUE

Nominal diameter: DN 350 - DN 900 - The torque values specifi ed

(Md) are based on dry media

Face-to-face: EN 558 Series 20 and are measured with air at

ISO 5752 Series 20 a temperature of 20 °C DN [mm] 350 400 450 500 600 700 750 800 900

API 609 Table 1

Flange - The values specifi ed are based Size [in] 14 16 18 20 24 28 30 32 36

accommodation: EN 1092 PN 10/16 on the initial breakaway torque MD [Nm] 720 980 1200 1500 2500 3000 3500 4500 6000

ASME Class 150 (disc disengages from seat,

ASME B16.47, Series A, Series B torque then drops)

AS 4087

Flange Surface - Dynamic torque specifi cation

Design: EN 1092 Form A/B available upon request

ASME RF, FF

Regarding the dimensioning of

Top fl ange: EN ISO 5211 actuators, please contact our

engineers. 12

Marking: EN 19 DN 350 - 600 special design, installation between fl anges

10

Tightness check: EN 12266 (Leakage rate A)

Temperature range: -40°C to +200°C 8

(depending on nominal diameter and

operation pressure) System Pressure PS (bar) 6 DN 350 - 600, installation between fl anges

Operating pressure: max. 6 bar (10 bar for special version) PRESSURE/TEMPERA- DN 700 - 900,

installation between fl anges

Vacuum: DN 350 - 600 max. 200mbar absolut TURE DIAGRAM 4 DN 350 - 900, end of line service

DN 700 - 900 max. 500mbar absolut

(with silicon elastomer inserts) 2

Double fl anged PTFE-lined butterfl y valve for shut-off and control 0

services in the chemical industry. -40 -20 0 20 40 60 80 100 120 140 160 180 200

System Temperature TS (°C)

FEATURES Pressure-Temperature-Diagram for valves with Silicone elastomer inserts.

Other elastomer inlays on request

- PTFE-lined butterfl y valve for chemically toxic and highly Vacuumservice for Sizes DN 350 - 600 to 200mbar absolut, depending on medium and temperature.

corrosive media Valve installation between fl anges

- Environmental protection via EBRO-Safety seal Vacuumservice for Sizes DN 700 - 900 to 500mbar absolut, depending on medium and temperature.

- Splitted body design Valve installation between fl anges

- Isolation height according to plant prescription

- Can be installed in any desired position K -VALUES

DN

- Maintenance-free v [mm] Size 20° 30° 40° Opening angle α° 70° 80° 90°

[in]

50°

60°

v

- Can be disassembled, material-specifi c recycling possible - The K -value [m³ per hour] is the

fl ow of water at a temperature of K v -values

- Material conform to FDA to EG 1935/2004 5°C to 30°C (41°F to 86°F) at 350 14 482 464 1042 2126 3625 5449 7507 9708

- Optional: Special design RWTÜV certifi ed to TA-Air/ VDI 2440 1 2 ∆p of 1 bar 400 16 627 603 1355 2765 4715 7088 9764 12627

- The K -values specifi ed are 450 18 790 761 1709 3488 5947 8939 12314 15925

v

based on tests carried out by the 500 20 973 936 2104 4293 7320 11003 15158 19602

GENERAL APPLICATIONS Delfter Hydraulics Laboratories,

the Netherlands 600 24 1394 1342 3016 6153 10492 15769 21724 28094

- Chemically highly corrosive and toxic media 700 28 1891 1820 4090 8345 14229 21388 29464 38104

- Purifi cation plants - Permissible velocity of fl ow 750 30 2167 2084 4685 9560 16303 24507 33763 43664

Vmax 4,5 m/s for liquids, 800 32 2463 2369 5323 10863 18525 27847 38365 49615

- Pharmaceutical industry Vmax 70 m/s for gases 900 36 3110 2991 6722 13718 23394 35166 48448 62655

- Adhesives, paper industry, dissolver

- The throttle function is linear at Subject to change without notice

- Paint manufacture and processing an angle 30° to 70°

Safety seal at both shaft ends:

- Food industry 1.Primary sealing by means of a belleville spring washer, trans-

- Chlorine production mitting prestress on the spherical segment area. For further values, please contact

our engineers.

2.Secondary sealing of the shaft by means of PTFE-Chevron and

- Processing of ore o-ring.

post@ebro-armaturen.com

T 212-A 2.2 www.ebro-armaturen.com

01.2019