Page 182 - Catalogue 2019

P. 182

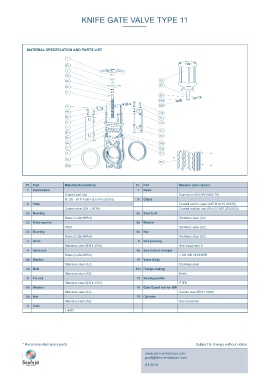

KNIFE GATE VALVE WB 11 KNIFE GATE VALVE TYPE 11

TECHNICAL DATA

MATERIAL SPEZIFICATION AND PARTS LIST

Nominal diameter: DN 50 - DN 300

1

Face-to-face: EN 558-1 Series 20 2c

ISO 5752 Reihe 20 2

2b

2a 18

Flange drilling: EN 1092 PN 10 25

ASME Class 150 1b

3

20

Marking: EN 19 20a

4 20b

Tightness check: EN 12266 (Leakage rate A) 4a 7g

ISO 5208 Class A 4b 7e

6 7f

Temperature range: max. 120°C 7 7c

8c

7d

8b

Actuators: Hand wheel, ratchet wrench, chain 8a 13b

wheel, bevel gear, pneumatic cylinder, 8 13a

electric motor, hydraulic cylinder 9 13

10

Operating pressure: DN 50 - DN 300: 10 bar 16

10c

The knife gate valve type WB is designed, manufactured, in-

spected and tested according to the European Pressure Equipment

Directive(PED 97/23/EC), category II module A1 and therefore CE Pt. Part Material (description) Pt. Part Material (description)

marked. 1 Hand wheel 7 Beam

Coated cast iron Aluminium (EN AW-6063-T6)

Ø 200 - Ø 315 (EN-JL1040 (GG25)) 8 Gland

FEATURES 2 Yoke Coated carbon steel (ASTM A216 (WCB))

- Box packing Twin Pack™ gives high operation reliability Coated steel (EN 1.0038) Coated nodular iron (EN-JS1050 (GGG50))

2a Bearing 8a Stud bolt

- Bi-directional sealing Brass (CuZn39Pb3) Stainless steel (A2)

- Casted one piece body 2b Slide washer 8b Washer

- Integrated fl angesealing 1. 2c Bearing POM 8c Nut Stainless steel (A2)

- Piggable design Brass (CuZn39Pb3) Stainless steel (A2)

3 Stem 9 Box packing

Stainless steel (EN 1.4016) See equipment D

4 Stem nut 9a Box bottom scraper

GENERAL APPLICATIONS 4a Washer Brass (CuZn39Pb3) 10 Valve Body > DN 200 UHMWPE

- Water and waste water Stainless steel (A2) Stainless steel

4b Bolt 10c Flange sealing

- Biogas plant

Stainless steel (A2) Nitrile

- Sugar industry 5 Tie rod 13 Sealing profi le

- Power plants and steel works Stainless steel (EN 1.4301) PTFE

2. 5a Washer 16 Gate Guard not for HW

- Chemical industry

Stainless steel (A2) Coated steel (EN 1.0038)

- Food and beverage industry 5b Nut 18 Cylinder

Stainless steel (A2) See datasheet

6 Gate

1. The integrated body seal ensures tightness when mounted 1.4401

between fl anges.

2. The pressure stressed sealing principle ensures permanent

tightness.

* Recommended spare parts Subject to change without notice

post@ebro-armaturen.com

WB 11 5.1 www.ebro-armaturen.com

01.2019