Page 47 - Catalogue 2019

P. 47

LUG TYPE BUTTERFLY VALVE Z 614-A LUG TYPE BUTTERFLY VALVE Z 614-A

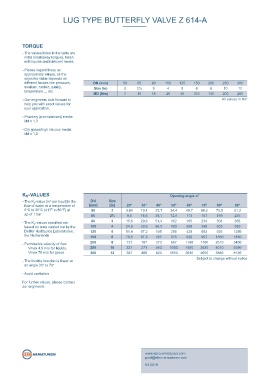

TECHNICAL DATA TORQUE

Nominal diameter: DN 50 - DN 300 - The values listed in the table are

initial breakaway torques, taken

Face-to-face: EN 558 Series 20 with liquids and lubricant media.

ISO 5752 Series 20 - Please regard these as

API 609 Table 1 approximate values, as the

objective value depends on

Flange accommodation: EN 1092 PN 10/16 different factors like pressure, DN (mm) 50 65 80 100 125 150 200 250 300

ASME Class 150 medium, rubber, quality, Size (in) 2 2½ 3 4 5 6 8 10 12

temperature ... etc.

MD (Nm) 7 15 18 28 45 110 140 200 280

Flange Surface Design: EN 1092 Form A/B - Our engineers look forward to All values in Nm

ASME RF, FF help you with exact values for

your application.

Top fl ange: EN ISO 5211

- Powdery (non-lubricant) media

Marking: EN 19 Md x 1,3

- Dry gases/high viscous media

Tightness check: EN 12266 (Leakage rate A) Md x 1,2

ISO 5208, Categroy 3

Temperature range: -10°C to +200°C (depending on

pressure, medium and material)

Operating pressure: max. 10 bar

Resilient seated lug type butterfl y valve for semi-corrosive media.

K -VALUES Opening angle α°

v

FEATURES - The K -value [m³ per hour] is the DN Size

v

fl ow of water at a temperature of [mm] [in] 20° 30° 40° 50° 60° 70° 80° 90°

- One piece disc/shaft 5°C to 30°C (41°F to 86°F) at 50 2 3,84 10,1 20,7 34,4 49,7 65,2 79,5 91,2

- Split body with stainless steel screws ∆p of 1 bar 65 2½ 9,5 16,6 39,1 72,6 113 157 199 235

- Insulation height as per plant regulations - The K -values specifi ed are 80 3 15,6 20,6 51,4 102 165 234 304 368

v

- Optional: Special design RWTÜV certifi ed to TA-Air/ VDI 2440 based on tests carried out by the 100 4 24,9 39,8 96,5 183 288 398 503 589

Delfter Hydraulics Laboratories, 125 5 51,8 67,2 135 256 428 652 926 1250

- Triple shaft bearing the Netherlands 150 6 76,5 97,3 197 375 629 957 1360 1830

- Disc`s sealing surface mirror polished 200 8 137 187 373 697 1160 1760 2510 3400

- Materials complying with FDA standards available - Permissible velocity of fl ow 250 10 227 271 563 1090 1850 2830 4010 5390

Vmax 4,5 m/s for liquids,

- Can be disassembled, material-specifi c recycling possible Vmax 70 m/s for gases 300 12 287 409 820 1550 2610 4050 5880 8120

- For paint and laquers, a silicone-free version is available - The throttle function is linear at Subject to change without notice

an angle 30° to 70°

- Avoid cavitation

GENERAL APPLICATIONS

For further values, please contact

- Food and beverage industry our engineers.

- Purifi cations plants

- Pharmaceutical industry

- Chemical and petrochemical industry

- Water and waste water industry

- Pneumatic materials handling technology The split body design allows quick and easy maintenance.

- Shipbuilding

- Power plants

- Civil engineering

post@ebro-armaturen.com

Z 614-A 1.10 www.ebro-armaturen.com

01.2019