Page 111 - Catalogue 2019

P. 111

QUALITY FEATURES HIGH PERFORMANCE BUTTERFLY VALVE HP 111 HIGH PERFORMANCE BUTTERFLY VALVE HP 111

HIGH PERFORMANCE VALVE HP 111

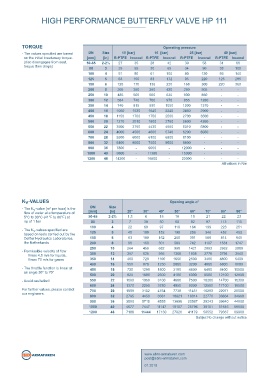

TECHNICAL DATA TORQUE Operating pressure

Nominal diameter: DN 50 - DN 1200 - The values specifi ed are based DN Size 10 [bar] 16 [bar] 25 [bar] 40 [bar]

Metal seated up to DN 800 max. PN 16 on the initial breakaway torque. [mm] [in] R-PTFE Inconel R-PTFE Inconel R-PTFE Inconel R-PTFE Inconel

(disc disengages from seat, 50-65 2-2½ 27 35 28 42 30 58 31 66

Face-to-face: EN 558 Series 20, optional Series 25 torque then drops) 80 3 28 55 30 65 34 90 38 100

ISO 5752 Series 20 100 4 51 90 61 100 80 120 93 140

STRAIGHT THROUGH API 609 Table 1 125 5 63 150 83 172 95 220 125 285

SHAFT 150 6 125 170 136 220 168 300 220 360

Flange accommodation: EN 1092 PN 10/16/25/40 (to DN 150)

ensures maximum bending EN 1092 PN 10/16/25 (DN 200-DN 1200) 200 8 205 350 260 430 280 505 - -

strength. ASME Class 150 250 10 485 505 550 620 600 860 - -

AS 4087 PN16/21 300 12 584 740 700 970 855 1280 - -

350 14 740 815 930 1050 1200 1370 - -

Flange Surface Design: EN 1092, Form A/B,

ASME RF,FF 400 16 1050 1530 1640 2240 2460 2900 - -

450 18 1150 1700 1750 2500 2700 3500 - -

Top fl ange: EN ISO 5211 500 20 1210 2010 1800 2760 2800 4260 - -

550 22 3500 3750 4430 4550 6010 6800 - -

Marking: EN 19 600 24 4000 4500 4600 5740 6200 8080 - -

700 28 5300 6000 6100 6800 8100 - - -

Tightness check Independent of fl ow-direction 800 32 6400 8000 7400 9500 9800 - - -

- for R-PTFE seat: EN 12266 (Leakage rate A)

- for Inconel seat: EN 12266 (Leakage rate B) 900 36 7800 - 9000 - 12000 - - -

ISO 5208, Category 3 1000 40 9800 - 11300 - 15000 - - -

MAINTENANCE-FREE BEARING 1200 48 14300 - 16500 - 22000 - - -

For all nominal diameters maintenance-free, Temperature range: -60°C to +600°C All values in Nm

overlong corrosion and temperatur e-resistant

bearings are used for exact centring of the Differential pressure: ≤ DN150 max. 40 bar

valve discs. Wafer type butterfl y valve in double-eccentric construction. Reliable > DN150 max. 25 bar

sealing even with extreme temperature and pressure conditions. Vacuum: up to 1mbar absolute

R-PTFE SEAT RING

The R-PTFE seat ring guaran- K -VALUES

FORCE-LOCKED tees absolute tightness and v DN Size Opening angle α°

v

CONNECTION compensates for wear. The seat FEATURES - The K -value [m³ per hour] is the [mm] [in] 20° 30° 40° 50° 60° 70° 80° 90°

ring can be replaced without fl ow of water at a temperature of

between disc and shaft. disassembling the shaft and - Shut-off and control of gaseous and liquid media 5°C to 30°C (41°F to 86°F) at 50-65 2-2½ 1,3 6 15 18 19 21 22 23

Low shear stresses thanks valve disc. - Disc has double-eccentric bearing ∆p of 1 bar 80 3 7 30 50 68 82 97 113 115

to tangentially arranged Alternative: Inconel or Fire-safe C Seat 100 4 22 60 97 119 164 199 223 251

v

tapered pins. - Centering pieces can be used as installation aid L Eccentricity shaft/seat - The K -values specifi ed are 125 5 45 100 152 195 256 346 452 493

- Two seat ring systems available: R-PTFE and Inconel based on tests carried out by the

Delfter Hydraulics Laboratories, 150 6 63 109 162 250 391 588 814 845

- Seal variants: the Netherlands 200 8 96 168 301 509 742 1107 1581 1747

soft-sealing (R-PTFE) max. 230°C

metallic sealing (Inconel) max. 600°C - Permissible velocity of fl ow 250 10 264 458 682 980 1421 2083 2882 2889

VALVE DISC fi re safe (PTFE/Inconel) max. 200°C Vmax 4,5 m/s for liquids, 300 12 397 625 956 1368 1938 2778 3794 3940

The valve disc has a double - Maintenance-free Vmax 70 m/s for gases 350 14 460 720 1100 1650 2500 3400 4800 5400

eccentric bearing design, Eccentricity shaft/ 400 16 550 870 1250 2000 3200 4800 6800 8080

resulting in low torques and - Long service life, even at high switching frequencies centerline pipeline - The throttle function is linear at 450 18 730 1200 1800 3100 4600 6400 8400 10500

low wear. All sealing surfaces - Fire safe BS 6755 part 2, API 607 5th Edition an angle 30° to 70° 500 20 920 1600 2600 4100 6000 8500 12100 12800

are machined.

- Avoid cavitation! 550 22 1090 1950 3100 4600 7500 10200 14700 15300

GENERAL APPLICATIONS C Pipeline For further values, please contact 600 24 1370 2250 3780 4950 9000 12500 17100 18500

L our engineers. 700 28 1999 3182 4764 7738 11451 16283 22071 25000

CLAMPING RING - Chemical and petrochemical industry 800 32 2795 4450 6661 10821 16014 22770 30864 34960

protects the seat ring from - Hot water and steam systems 900 36 3590 5715 8555 13898 20567 29243 39640 44900

abrasion and erosion. - District heat supply 1000 40 4677 7447 11147 18107 26796 38101 51646 58500

- Vacuum systems 1200 48 7188 11444 17130 27826 41179 58552 79367 89900

Subject to change without notice

- Shipbuilding

- Gas process technology

- Heavy duty services

post@ebro-armaturen.com

HP 111 3.1 www.ebro-armaturen.com

01.2019