Page 34 - Catalogue 2019

P. 34

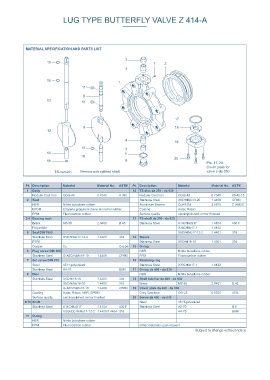

LUG TYPE BUTTERFLY VALVE Z 414-A LUG TYPE BUTTERFLY VALVE Z 414-A

MATERIAL SPECIFICATION AND PARTS LIST

ØF ØF

ØJ G 3

15 7 2

□G

H 2 4

H 1

15

1

Optional shaft end: 11

Double flat acc.

to EN ISO 5211 9

13

A 11

C

Ø Di 17

ØD Z

8 18

12

B 4

19

11 3

14 5

10

E 16 6 20

Pts. 17-20:

Cover plate for

Z 414-A with bare shaft end TS-version Version with splitted shaft valve ≥ da 350

Pt. Description Material Material No. ASTM Pt. Description Material Material No. ASTM

Dimensions [mm]

1 Body 12 TS-disc da 250 - da 630

Nodular Cast Iron GGG-40 0.7040 A 395 Nodular Cast Iron GGG-40 0.7040 60-40-18

DN Ø = da SDR 11 SDR 17/ 17,6 SDR 33 2 Seat Stainless Steel X6CrNiMo10-20 1.4408 CF8M

[mm] [mm] A B C ØD ØDi Z ØD ØDi Z ØD ØDi Z E ØF Flange G H1 H2 ØJ Weight NBR Nitrile butadiene rubber Aluminium Bronze CuAl10Ni 2.0975 C 95800

[kg]

EPDM Ethylene propylene diene monomer rubber Coating Halar, Rilsan

40 50 113 66 179 80 37 22 80 37 22 80 37 22 33 54 F04 11 12 19 14 4,0

FPM

50 63 126 84 210 95 48,5 25 95 48,5 25 95 48,5 25 43 54 F04 11 12 19 14 4,8 3/4 Bearing bush Fluorocarbon rubber 13 Surface quality electropolished, mirror finished

TS-shaft da 250 - da 630

65 75 134 93 227 115 63,5 45 115 63,5 45 115 63,5 45 46 54 F04 11 12 19 14 5,5 Brass MS 58 2.0401 B 45 Stainless Steel X14CrMoS17 1.4104 430 F

80 90 157 104 261 138 78,5 65 138 78,5 65 138 78,5 65 46 65 F05 14 16 25 18 8,6 Polyamide X39CrMo17-1 1.4122

100 110 167 115 282 158 98,5 85 158 98,5 85 158 98,5 85 52 65 F05 14 16 25 18 9,8 5 Seal DIN 7603 X5CrNiMo17-12-2 1.4401 316

100 125 167 115 282 158 98,5 85 158 98,5 85 158 98,5 85 52 65 F05 14 16 25 18 11,0 Stainless Steel X5CrNiMo17-12-2 1.4401 316 14 Sleeve

125 140 180 127 307 166 111,2 98 188 123,5 111 188 123,5 111 56 65 F05 14 16 25 18 13,5 PTFE Stainless Steel X5CrNi18-10 1.4301 304

150 160 203 150 353 186 123,2 111 186 123,2 111 212 148 139 56 90 F07 17 19 30 22 16,0 6 Copper Cu Copper 15 O-ring Nitrile butadiene rubber

Plug screw DIN 908

NBR

150 180 203 150 353 212 148 139 212 148 139 212 148 139 56 90 F07 17 19 30 22 15,5 Stainless Steel G-X6CrNiMo18-10 1.4408 CF8M FPM Fluorocarbon rubber

200 200 228 176 404 226 161,5 151 226 161,5 151 250 182 173 60 90 F07 17 19 30 22 22,0 7 Set screw DIN 915 16 Retaining ring

200 225 228 176 404 250 182 173 268 198,2 190 268 198,2 190 60 90 F07 17 19 30 22 23,5 Steel 45 H galvanized Stainless Steel X39CrMo17-1 1.4122

250 250 266 212 478 268 198,2 188 268 198,2 188 308 224,3 215 68 90 F07 17 19 30 22 34,0 Stainless Steel A4-70 B8M 17 O-ring da 400 - da 630

250 280 266 212 478 315 224,3 215 - - - - - - 68 125 F07 17 24 39 30 37,0 8 Disc NBR Nitrile butadiene rubber

250 280 266 212 478 - - - 320 248 240 320 248 240 68 125 F10 22 24 39 30 37,0 Stainless Steel X5CrNi18-10 1.4301 304 18 Shaft retainer da 400 - da 630

300 315 293 237 528 358 255 244 358 255 244 358 279,6 270 78 125 F10 22 24 39 30 48,0 X5CrNiMo18-10 1.4401 316 19 Brass MS 58 2.0401 B 45

1.4408

Cover plate da 400 - da 630

CF8M

G-X6CrNiMo18-10

350 355 332 269 601 365 285,7 272 392 311,4 299 392 311,4 299 92 125 F10 22 24 39 30 62,0 Coating Halar, Rilsan, NBR, EPDM Grey Cast Iron GG-25 0.6025 40 B

400 400 363 314 677 428 327 312 437 349,6 336 437 349,6 336 102 150 F12 ** ** - 40 96,0* Surface quality electropolished, mirror finished 20 Screw da 400 - da 630

500 450 437 405 842 454 365,8 345 454 365,8 345 508 409 390 127 150 F12 ** ** - 40 145,0* 9/10 Shaft Steel 45 H galvanized

500 500 437 405 842 508 409 390 546 439,6 422 546 439,6 422 127 150 F12 ** ** - 40 154,0* Stainless Steel X14CrMoS17 1.4104 430 F Stainless Steel A2-70 B 8

600 560 475 418 893 530 426 412 - - - - - - 127 210 F16 ** ** - 50 165,0* X5/(X2)CrNiMo17-12-2 1.4401/1.4404 316 A4-70 B8M

600 630 475 418 893 574 488 473 - - - - - - 127 211 F16 ** ** - 50 178,0* 11 O-ring

NBR Nitrile butadiene rubber

* through going shaft only (TS-version) Subject to change without notice FPM Fluorocarbon rubber Other materials upon request

** according to the mounted actuator

Subject to change without notice