Page 196 - Catalogue 2019

P. 196

KNIFE GATE VALVE XV KNIFE GATE VALVE XV

TECHNICAL DATA

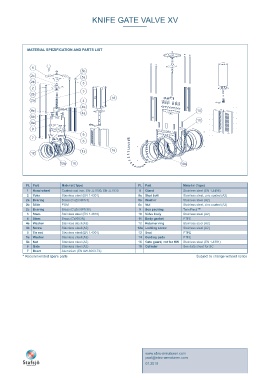

MATERIAL SPEZIFICATION AND PARTS LIST

Nominal diameter: DN 80 - DN 600

Larger nominal diameters on request.

Face-to-face: DN 80 - DN 300 EN 558 Series 20 1 5b

DN 350 - DN 600 works standard 2c 5a

2b 5

Flange Surface Design: EN 1092 PN 10

ASME Class 150 2 3

2b

18

Marking: EN 19 2a 4

4b

Tightness check: EN 12266 (Leakage rate A) 8c 4a 14

ISO 5208 Class A 8b

8a 11

Temperature range: max. 180°C 8

9

Actuators: Hand wheel, chain wheel, 7 6

ratched wrench, pneumatic cylinder,

electric motor, hydraulic cylinder 13 16

12

Operating pressure: DN 80 - DN 350: 10 bar

DN 400 - DN 600: 6 bar 12a 10 10a

Knife gate valve for liquids with high solids content up to 8%.

Pt. Part Material (Type) Pt. Part Material (Type)

1 Hand wheel Coated cast iron, EN-JL1040, EN-JL1030 8 Gland Stainless steel (EN 1.4408)

2 Yoke Stainless steel (EN 1.4301) 8a Stud bolt Stainless steel, zinc coated (A2)

FEATURES 2a Bearing Brass (CuZn39Pb3) 8b Washer Stainless steel (A2)

2b Slide POM 8c Nut Stainless steel, zinc coated (A2)

- Box packing TwinPack™ gives high operation reliability 2c Bearing Brass (CuZn39Pb30) 9 Box packing Twin Pack™

3 Stem Stainless steel (EN 1.4016) 10 Valve body Stainless steel (A2)

- One side lugging, bi-directional sealing Slide 4 Stem Brass (CW603N) 11 Body gasket PTFE

- Easy replacement of seat by mechanically locked retainer ring Stud bolt 4a Washer Stainless steel (A2) 12 Retainer ring Stainless steel (A2)

- Low-maintenance Gland follower Screw nut and washer 4b Screw Stainless steel (A2) 12a Locking screw Stainless steel (A2)

- High resistance against water hammer 5 Tie rod Stainless steel (EN 1.4301) 13 Seat PTFE

5a Washer Stainless steel (A2) 14 Guiding pads PTFE

- Great differential pressure possible 5b Nut Stainless steel (A2) 16 Gate guard, not for HW Stainless steel (EN 1.4301)

6 Gate Stainless steel (A2) 18 Cylinder See data sheet for SC

Packing gland O-ring 7 Beam Aluminium (EN AW-6063-T6)

* Recommended spare parts Subject to change without notice

Flange ring Seat

GENERAL APPLICATIONS

- Process technology

- Pulp and paper

- Granulates, bulk solids and powder

Body

6.3

XV 5.5 www.ebro-armaturen.com

post@ebro-armaturen.com

XV 01.2019