Page 27 - Catalogue 2019

P. 27

DOUBLE FLANGED BUTTERFLY VALVE F012-K1/ WN DOUBLE FLANGED BUTTERFLY VALVE F012-K1 / WN DOUBLE FLANGED BUTTERFLY VALVE F012-K1/ WN

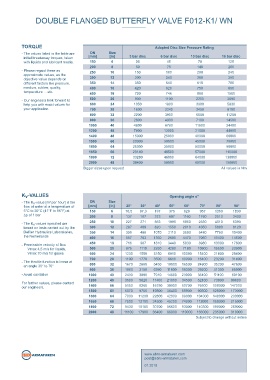

The shaft sealing of centric soft-seated butterfl y valves is primarily TECHNICAL DATA TORQUE Adapted Disc Size Pressure Rating

effected by the surface pressure between the valve disc and the DN Size

liner. Especially with large nominal diameters from DN600 and high Nominal diameter: DN 150 - DN 2000 - The values listed in the table are [mm] [in] 3 bar disc 6 bar disc 10 bar disc 16 bar disc

pressures more than 16 bar, the simple surface pressure may no (bigger sizes upon request) initial breakaway torques, taken 150 6 36 45 78 125

longer be suffi cient. with liquids and lubricant media.

Face-to-face: EN 558 Series 20 200 8 59 76 140 200

EBRO has designed an adjustable shaft seal which makes it ISO 5752 Series 20 - Please regard these as 250 10 150 180 200 240

possible to increase the surface pressure in the shaft passage area API 609 Table1 approximate values, as the 300 12 200 240 280 360

so even large valves can operate at pressures of up to 25 bar. Works standard objective value depends on

different factors like pressure, 350 14 350 540 610 700

A further advantage of this design is that the shaft seal can be Flange accommodation: EN 1092 PN 6/10/16 medium, rubber, quality, 400 16 420 620 750 850

adjusted by tightening the screws and thus readjusted if necessary. ASME Class 150 temperature ... etc. 450 18 720 746 860 1500

AS/NZS 4087 PN 16 - Our engineers look forward to 500 20 900 1100 2255 3690

Flange accommodation for works help you with exact values for 600 24 1050 1800 3000 5830

standard on request your application. 700 28 1600 2240 3450 8100

800 32 2200 3900 6600 11200

Flange Surface Design: EN 1092 Form A/B

ASME RF, FF 900 36 2800 4900 7100 14500

1000 40 4800 6760 11500 24400

Top fl ange: EN ISO 5211 1200 48 7800 12000 21000 44000

1400 48 15000 25000 40000 60000

Marking: EN 19 1500 60 20000 30000 45000 75000

1600 64 25000 35000 50000 90000

Tightness check: EN 12266 (Leakage rate A)

ISO 5208, Kategorie 3 1650 66 29140 40500 57000 110000

1800 72 33280 46000 64000 130000

Temperature range: -40°C to +200°C (depending on 2000 48 38400 50000 69000 150000

pressure, medium and material) Bigger sizes upon request All values in Nm

Operating pressure: 16 bar (others on request)

Adjustable bearings ensure tightness even with max. pressure loads. Double fl anged butterfl y valve with short construction length to be

This feature allows refi xing during operation. used in heavy duty applications.

K -VALUES Opening angle α°

v

FEATURES - The K -value [m³ per hour] is the DN Size

v

fl ow of water at a temperature of [mm] [in] 20° 30° 40° 50° 60° 70° 80° 90°

- Absolutely tight sealing with fl ow in either direction 5°C to 30°C (41°F to 86°F) at 150 6 76,5 97,3 197 375 629 957 1360 1830

- The valve body and disc are accurately machined which results ∆p of 1 bar 200 8 137 187 373 697 1160 1760 2510 3400

in low operating torque and long service life and reliability - The K -values specifi ed are 250 10 227 271 563 1090 1850 2830 4010 5390

v

- Triple shaft bearings prevent shaft defl ection and guarantee based on tests carried out by the 300 12 287 409 820 1550 2610 4050 5880 8120

optimum guidance even after many years of operating service Delfter Hydraulics Laboratories, 350 14 399 488 1070 2110 3590 5480 7760 10400

- Can be disassembled, material-specifi c recycling possible the Netherlands 400 16 557 703 1360 2600 4470 7060 10400 14600

- Single fl ange mounting is possible - Permissible velocity of fl ow 450 18 716 907 1810 3440 5830 8980 13000 17800

- Can be installed in any desired position Vmax 4,5 m/s for liquids, 500 20 875 1110 2250 4280 7180 10900 15500 20900

Vmax 70 m/s for gases 600 24 1230 1550 3150 6010 10090 15400 21800 29400

- Maintenance-free 700 28 1100 1770 3590 6610 10900 16400 23200 31400

- Fully repairable valve - The throttle function is linear at 800 32 1670 2680 5450 10000 16500 24900 35200 47600

an angle 30° to 70°

900 36 1960 3150 6390 11800 19300 29200 41300 55900

- Avoid cavitation 1000 40 2430 3890 7910 14600 23900 36100 51100 69100

1200 48 3500 5620 11400 21000 34500 52100 73800 99800

GENERAL APPLICATIONS For further values, please contact

our engineers. 1400 66 5150 8260 16780 30900 50700 76500 108000 147000

- Offshore 1500 60 6070 9750 19800 36400 59900 90300 128000 173000

1600 64 7000 11200 22800 42000 69000 104000 148000 200000

-Water and waste water technology

1650 66 7500 12100 24500 45200 74200 112000 159000 215000

- Shipbuilding

1800 72 9430 15100 30700 56600 93000 140300 199000 269000

- Power plants 2000 48 11100 17900 36400 66900 110000 166000 235000 318000

Subject to change without notice

post@ebro-armaturen.com

F012-K1/ WN 1.5 www.ebro-armaturen.com

01.2019