Page 236 - Catalogue 2019

P. 236

WAFER TYPE CHECK VALVE RSK WAFER TYPE CHECK VALVE RSK

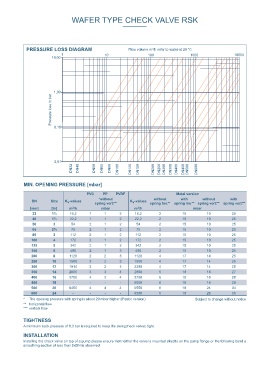

PRESSURE LOSS DIAGRAM Flow volume m³/h refer to water at 20 °C

1 10 100 1000 10000

10,00

Detail X

Construction II

E

x

1,00

Pressure loss in bar

Ø F

Ø A Ø D Ø C

0,10

G

B

0,01

DN32 DN40 DN50 DN65 DN80 DN100 DN125 DN150 DN200 DN250 DN300 DN350 DN400 DN450 DN500 DN600

Wafer type check valve RSK standard (plastic/metal version)

Dimensions [mm] MIN. OPENING PRESSURE [mbar]

Metal without Metal with

DN Size Plastic manual emergency manual emergency Weight [kg] PVC PP PVDF Metal version

switch switch DN Size K -values *without K -values without with without with

B B B B B B v spring vert.*** v spring hor.** spring hor.** spring vert.*** spring vert.***

3

3

[mm] [in] A without with without with without with C D E F G Pla- Metal [mm] [in] m /h mbar m /h mbar

stic

spring spring spring spring spring spring 32 1¼ 16,2 1 1 2 16,2 2 15 10 25

32 1¼ 85 15 15 15 15 - - 18 59 22 37 25 0,1 0,5 40 1½ 22,2 1 1 2 22,2 2 15 10 25

40 1½ 95 16 16 16 16 - - 22 72 25 43 28 0,1 0,8 50 2 54 2 1 2 54 2 15 10 25

50 2 109 18 18 17/14** 17/14** 19 19 32 86 37 54 29 0,2 1,0 65 2½ 75 2 1 2 75 2 15 10 25

65 2½ 129 20 20 17/14** 17/14** 19 19 40 105/109* 50 70 29 0,2 1,4 80 3 112 2 1 2 112 2 15 10 25

80 3 144 20 20 17/14** 17/14** 20 20 54 119 61 82 29 0,3 1,8 100 4 172 2 1 2 172 2 15 10 25

100 4 164 23 23 21/18** 21/18** 23 23 70 146 77 106 31 0,4 2,9 125 5 342 2 1 2 342 2 15 10 25

125 5 195 23 23 18 22/18** 24 24 92 173 94/98* 131 35 0,5 3,9 150 6 490 2 1 3 490 2 15 10 25

150 6 220 26 26 20 26/20** 29 29 105 197 100/120* 159 35 0,7 4,6 200 8 1128 2 2 3 1128 4 17 14 25

200 8 275 34 34 22 29/22** 30 30 154 255 152/160* 207 38 1,4 5,0 250 10 1500 3 2 3 1500 4 17 14 25

250 10 330 40 40 26 36/26** 35 35 192 312 180/190* 260 41 2,4 13,0 300 12 1914 3 2 3 2290 4 17 14 25

300 12 380 45 45 32 43/32** 43 43 227 363 215/220* 309 41 3,5 23,0 350 14 2800 3 3 4 2890 6 18 18 27

350 14 440 49 49 38 47/38** 48 48 266 416 245/250* 341 54 5,1 33,5 400 16 3700 4 3 4 3700 6 18 18 28

400 16 491 65 65 44 53/44** - - 310 467 285/290* 392 55 7,3 52,0 450 18 - - - - 5000 6 18 18 28

450 18 541 68 78 52 - - - 350 520 330 443 58 - - 500 20 6450 4 4 4 6550 6 18 24 34

500 20 596 78 87 58 68/58** - - 400 550 385/390* 493 60 - 94,0 600 24 - - - - 9500 6 18 26 36

600 24 698 97 97 62 - 486 659/660* 470 595 70 - - * The opening pressure with spring is about 20 mbar higher (Plastic version) Subject to change without notice

*metallic version ** horizontal flow

**versions with aluminum bronze body *** vertical flow

Type RSK 1 RSK 1.1 RSK 3 RSK 4 RSK 5 RSK 6 RSK 6.1

Body Aluminium Aluminium 1.4301 PVC PP 1.4408 1.4571

TIGHTNESS

Disc 1.4408 1.4571 1.4408 PVC PP 1.4408 1.4571 A minimum back pressure of 0,3 bar is required to keep the swingcheck valves tight.

Type RSK 8 RSK 9 RSK 9.1 RSK 13 RSK 19 RSK 19.1 RSK 19.2 INSTALLATION

Steel, Nickel Steel, Nickel Aluminum bronze Aluminum bronze Aluminum bronze Installing the check valve on top of a pump please ensure that neither the valve is mounted directly on the pump flange or the following bend a

Body PVDF Hastelloy C4 smoothing section of less than 5xDN is observed.

Plated Plated 2.0975 2.0975 2.0975

Aluminum bronze

Disc PVDF 1.4408 1.4571 Hastelloy C4 2.0975 1.4571 1.4408

Subject to change without notice